3D Metrology Services – Best Technologies and Equipment

3D Engineering Solutions offers state-of-the-art metrology services, including dimensional inspection, quality certifications, and programming. As an ISO/IEC 17025 accredited laboratory, 3D Engineering adheres to the highest standards. Whether you seek first article inspection (FAI) in accordance with AS9100 verification, direct scan to CAD comparison reports, assistance with quality control or other operations, 3D Engineering offers best-in-class and customizable metrology support.

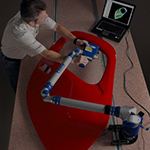

Our team of engineers can travel to your location or work remotely to provide the data you need. 3DES completes entire projects or can provide portions to augment your internal resources. We employ the latest available 3D scanning technologies and equipment for your manufacturing and design measurement needs.

Our beautiful temperature-controlled and humidity monitored white floor labs house the best precision measurement equipment from the best OEMs. We feature both touch and touchless data collection methods that suit all industries from automotive, medical, aerospace, consumer products, and others.

Learn more about how we can support your 3D metrology needs.

What Are Metrology Services?

Metrology is the study of measurement. As degreed engineers, we have a passion for providing you with quick and accurate data and analysis to support your quality control operations.

Our engineers are trained in each data collection technology and software that we use. During training, they learn the strengths and weaknesses of each type of equipment and are able to intelligently confirm to you which measurement systems are best for your project. So your project will have the benefit of an engineer skilled in all metrology applications. And for your urgent needs, we can assign multiple engineers to your project on a shift basis for up to 24/7 support!

We have a large depth of experience that can be brought to bear with even the non-standard dimensioning practices that we encounter. In all cases where we encounter a non-standard practice, we make a note in our reports method section on how we addressed that specific issue, such as reverse engineering.

Touchless Data Collection Technologies

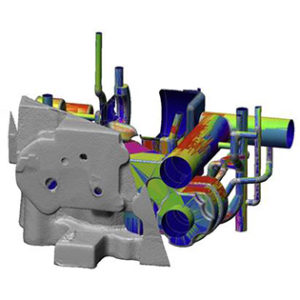

Our touchless data collection technologies include: Industrial computed tomography (CT) scanning, White Light and Blue Light Structured Light Scanning, Short and Long Range Laser Scanning, X-ray, Vision System Inspection and Confocal White Light Sensor Scanning (CFS).

Each of these measurement systems do not require physical contact with an actual object and each has strengths over the others in time required to scan data, accuracy, and material suitability. Our engineers have been taught how to select the right technology for your needs. They can even use combinations of multiple technologies together to give you the best selection of quality and cost.

3D Engineering Solutions is able to handle measurements of any size from tiny endoscopic surgical components to bridges, ships and buildings! We will carefully tailor your inspection project to meet your print tolerance requirements using 3D scanning and other leading metrology practices. We can even perform reverse engineering to solve challenging problems.

We also provide training services in any of the metrology areas we have proficiency in. This includes data collection, reporting and metrology methods like 3D scanning. Our training is often superior to the OEMs training in that we do not train manuals with example parts that always work correctly each time, but rather use your prints, equipment and actual parts.

We offer dimensional inspection, scan to CAD model comparison, First Article Inspection (FAI), Production Part Approval Process Inspection (PPAP), capability studies, gage dimensional verification, part programming and Gage Repeatability and Reproducibility (GR&R) studies.

If you have a new measurement requirement or application, we can also make recommendations on what is needed for your project. From structured light scanning to point cloud scanning and beyond, we provide highly accurate 3D metrology that you can count on.

The Best Services for Your Needs

You may be looking for a metrology services provider because your internal staff and equipment is fully booked with production needs and they are unable to complete your quality control inspection requirements in a timely manner. Or you do not yet possess one of our many quality inspection technologies like 3D scanning that are required for a specific project. Alternatively, your customer may have a requirement for a certified 3rd party inspection.

In any of these cases, 3D Engineering Solutions can satisfy your needs. Because of the extensive cross-training of our engineers, we can also provide 24/7 dimensional inspection for small to large quantities of components in any of our covered technologies.

FAQs

What is 3D metrology?

3D metrology is the study of measurement in three dimensions. Geometric data is collected using a metrology device like a coordinate measuring machine to provide precision measurements.

How do 3D measurements work?

3D measurements work by collecting many different data points from a physical object including size, shape, and even color. This data comes together to create a three-dimensional model.

How do you measure a 3D object?

3D objects are usually measured by calculating height times width times depth or diameter. The sum of these numbers represents the physical size of the object.