First Article Inspection (FIA) and how it Benefits the Manufacturing Process

3D Engineering Solutions is an accredited 3rd party provider of First Article Inspections. We are ISO17025 certified to provide FAI dimensional measurement inspection services. We employ a wide range of contact and non-contact metrology equipment for this purpose.

Our goal is to augment your internal capabilities and capacities. First Article Inspections demand a large amount of resources to conduct and can easily bog down the throughput of your quality department. Using our service allows your quality staff to maintain their current throughput for existing production requirements while satisfying your customers’ needs to validate compliance of your product to the print.

First Article Inspection Service

What FAI is:

A First Article Inspection is a part of the production process used to verify to the design owners (internal design engineers or external customers) that the components and assemblies that are manufactured are initially correct to the print. If a design change occurs, tool change or repair happens, a new supplier is added or a sufficiently long lapse in production of that component occurs, then a new First Article Inspection should happen to verify that the tooling and process continues to have the ability to meet the specification requirements. Additional inspections may be required after an FAI through the life of the product to ensure product control. The FAI helps document and assure that the components satisfy the Production Part Approval Process (PPAP) requirements.

How Our FAI Process Helps:

We conduct FAIs continually and are set up to provide this type of service. Programming new inspections is one of the most time consuming measurement activities for a quality organization. We have developed a high level of proficiency in interpreting complex print requirements and providing these dimensional measurement inspection results in an efficient manner.

Additional Benefits

Modern scanning inspection equipment has the added benefit of being able to compare part change over time and thereby can give an indication of tool wear. This is done by comparing original scan data to new scan data in a ‘scan to scan’ comparison color map. Since internal quality organizations are often called upon to help troubleshoot manufacturing issues, a scan to scan comparison can be a useful tool.

Our Capability, Capacity & Experience and its Impact on the Manufacturing Process

Capability:

We have a vast array of dimensional measurement equipment at our lab including: Laser Scanning, Blue Light Structured Light Scanning, White Light Structured Light Scanning, probe CMM, Vision, Confocal White Light Scanner, Industrial CT scanning as well as the common tools such as digital height gage, comparator, micrometers, calipers, pins, blocks, etc. Our 24,000 square foot facility includes 10,000+ square foot temperature controlled dimensional measurement lab space. All of our degreed engineers is proficient in each of the technologies that we employ. This large tool box allows us to use the right equipment for each measurement without compromise. Provide us with your 3D CAD files and prints and we will employ the proper technology for your dimensional measurement requirements. If you only have 2D prints, we can work with that as well.

Our engineering staff is each certified in GD&T. We are experts at the interpretation of print specifications and application of those interpretations in dimensional measurement.

Capactiy:

We have a large staff to handle heavy inspection loads and do offer 24/7 service for those critical timing requirements. Many quality departments are inundated with first article inspection requirements as new products come out. Use our large staff to push these inspections through in a short time while not impacting your existing production inspection work load. We find many quality departments understaffed and overworked due to these sporadic FAI requirements that tend to eclipse capacity. Dimensional measurement is not an area that you want to rush results from an already overburdened staff. That can to lead to higher error rates and the need for repeat inspections.

Experience

Through our long history as a company we have completed thousands of inspections and First Articles. We cover all industries including: aerospace (AS9102), automotive, medical, fire arms (3DES is a type 7 FFL) and consumer products. First article inspections are important for every industry, but aerospace is the one that is most strict in its adherence due to obvious safety concerns and longer term litigation possibilities. Because of this, it is important to use an independent 3rd party with a large amount of specific industry experience, application knowledge and proficiency. At 3D Engineering Solutions, we have that knowledge and experience and we have been tested over many years and in many industries.

ISO17025 Accreditation and FAI

Quality Control And Our Quality Management System:

We have held our ISO17025 accreditation through ILAC/ANAB since shortly after our inception in 2007. Our Quality Management System (available upon request) has changed and improved over the years to match new ISO standards and learnings. We are audited both internally and externally to our standard and participate in independent external proficiency testing on a yearly basis for dimensional measurement. As gaps are found in our system we implement changes through a corrective action system. This rigorous process provides our customers and their end customers with additional confidence in the measurements that we provide.

What To Look For And Watch Out For:

Non-accredited sources of dimensional inspection cannot guarantee a high level of training or proficiency, calibrated equipment from a reliable source (if calibrated at all) or rigorous procedures to ensure consistency in results. Why? – Because they have no outside source to hold them accountable.

Understanding measurement uncertainty in the equipment being used for your inspection is of great importance. Non-accredited sources will sometimes list the accuracies of the equipment they use (most do not). However, accuracy does not tell the full story.

Look for measurement uncertainty statements in your inspection reports. Measurement uncertainty gives a better overall picture of the uncertainties and confidence intervals involved in a measurement. Measurement uncertainty includes the equipment OEM’s stated accuracy but also includes other effects that impact the measurand such as: equipment calibration uncertainty, environmental effects, operator repeatability influences, equipment resolution and the like.

ISO9001 vs ISO17025 vs AS9100 – There is a difference! Be sure to read the linked article to gain a better understanding of why you want to only use an ISO17025 accredited service for your 3rd party FAI requirements.

Another item to be wary of is the total influence from measurement uncertainty on the measurement from a standpoint of percentage of full tolerance zone. Ideally and by convention, the uncertainty from a measurement is kept to at least 10x smaller than the tolerance so that it is only affecting less than 10% of the tolerance zone. Anything less than 4x should be looked at with caution. Many inspection services do not even pause to consider this.

3D Engineering Solutions avoids these and other errors through our rigorous process which is continually audited by independent sources.

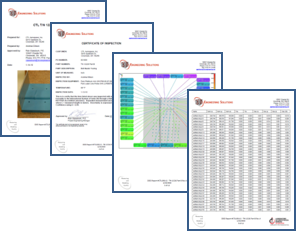

The Inspection Report:

We believe that the inspection report should serve as a roadmap to recreating the data if needed. It should indicate all of the equipment used in the inspection, the measurement uncertainties associated with that equipment, lab or test conditions and a method section detailing the inspection and any assumptions or special processes used. You no longer have to accept a spreadsheet full of data only with no knowledge of how it was created.

We believe that the inspection report should serve as a roadmap to recreating the data if needed. It should indicate all of the equipment used in the inspection, the measurement uncertainties associated with that equipment, lab or test conditions and a method section detailing the inspection and any assumptions or special processes used. You no longer have to accept a spreadsheet full of data only with no knowledge of how it was created.

Please contact us at 3D Engineering Solutions today for all of your First Article Inspection needs. For more information check out our blog: First Article Inspection – A Comprehensive Guide on How to Perform an FAI.