Aligning Multiple Scans of a Single Object

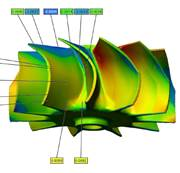

Something people may not think about is the processes used to align multiple scans of a single object, as many parts require more than one scan to fully cover the object. Sometimes the part may be too large for the equipment to cover from one spot, or a part may need to be flipped over to scan the bottom. When this happens, two or more separate scans must be conducted by scanning the part in one position, then moving it and scanning again. Some parts have enough unique features to use for alignment, by signaling the software to use those features as the basis for aligning.

Continue Reading →