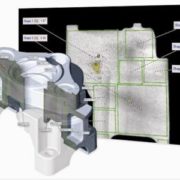

Measuring Large Volume Parts with the O-Inspect 863 – Patterns in Calypso

With the addition of our latest CMM, the Zeiss O-Inspect 863, we are now able to measure large volumes of parts with the high measurement accuracy that the system’s white light focal sensor, camera and scanning probe have to offer.

Continue Reading →